Modern, quick, and fully-automated. Pyka’s signature electrical plane are remodeling the way forward for cargo transportation with sooner deliveries, improved security, and effectivity–from ease in taking off to flying in harsh climate circumstances.

The increasing product line of the California-based aviation firm continues to showcase their spectacular imaginative and prescient and flexibility, fueled by 3D printing. After mastering design and manufacturing of autonomous plane for agricultural functions like crop-spraying, Pyka transitioned into growing new options for middle-mile cargo transport.

Market Demand Required Modifications to Authentic Pyka Plane Designs

Pyka had nice success in producing their first electrical airplane, the Pelican Spray, and dealing in different aerial functions. They shortly piqued the curiosity of cargo-transport firms.

“Market leaders thought our expertise could be completely suited to what they wanted in shifting cargo,” mentioned Jason Petersen, Senior Mechanical Design Engineer at Pyka. “Provide chain influenced {that a} bit, however total, the aviation business was primed to advance and our digital aviation expertise was essentially the most subtle.”

Assembly the wants of recent shoppers meant making adjustments to current expertise. Pyka spent a 12 months modifying and creating new plane that might fly longer distances, maintain extra cargo, and would even be simple to keep up.

3D Printing Accelerated Product Improvement & Manufacturing

3D printing performed a big function in streamlining these modifications, and has continued to speed up Pyka’s manufacturing improvement and manufacturing processes. “Persons are usually shocked at how usually we use 3D printing in our plane,” mentioned Petersen.

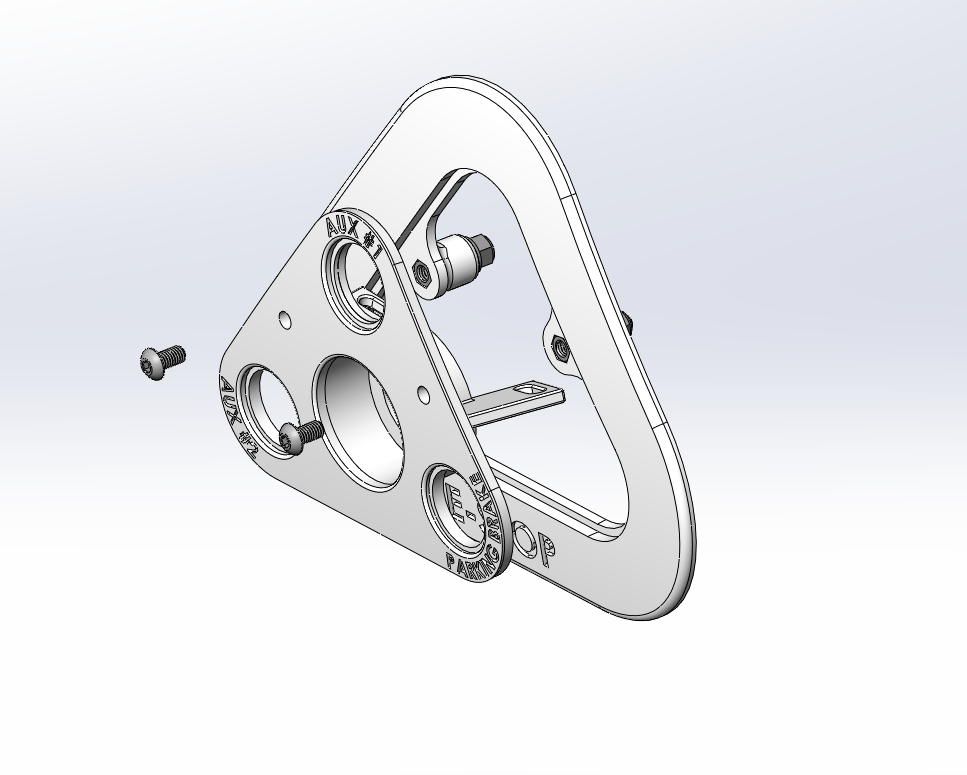

Whereas there are dozens of 3D printed elements on every plane, some examples embrace waterproofed fairings, instances for wires and smaller electronics, latch mounts, and user-interface panels. Pyka experiences ease in designing round any issues, with out ever having to fret about ‘manufacturability’ of elements in 3D printing.

“Design freedom performs a big function in permitting us to prototype and make adjustments, strategically inserting sure supplies the place we all know added energy is critical within the plane’s geometry,” mentioned Petersen. “With 3D printing, we will create a lot lighter elements for advanced constructions, compared to injection molding or machining.”

Affordability in prototyping and manufacturing is a significant benefit because the Pyka staff is continually testing elements and on the lookout for methods to boost their merchandise, often revising no less than one 3D printed prototype per week. Their design staff uploads 3D fashions to Shapeways shortly, receives on the spot quotes and printability evaluation, after which additionally has the benefit of referring again to those self same digital information for on-demand additive manufacturing.

Superior 3D Printing Thermoplastics Meet Pyka’s Rising Wants

The autonomous plane designers leverage expertise like Selective Laser Sintering and Multi Jet Fusion due to the benefit in redesigning elements, and sustaining them later. Supplies like Nylon 12 [Versatile Plastic] make it doable to create sturdy but versatile elements, whereas MJF Plastic PA12 gives crucial properties like moisture- and chemical-resistance.

“We’ve experimented with metallic 3D printing and different supplies like Polypropylene, however I discover we all the time find yourself going again to the opposite supplies due to their glorious energy properties. We’re used to working with them, the end result is predictable, and the value level is simply laborious to beat!” mentioned Petersen.

Entry to superior, sturdy supplies is essential as a result of Pyka makes use of so most of the 3D printed elements to carry necessary plane parts in place–when putting in an element requiring full accuracy on high of a wing, for instance–or on a curved space of the plane.

Presently, the typical Pyka plane contains 60-80 3D printed elements. The corporate’s speedy growth in agriculture and cargo transport is fueled by their capacity to simplify design and manufacturing with additive manufacturing, leading to 11 plane constructed and 45 extra deliberate for deployment sooner or later.