3D Programs has launched a brand new 3D printer and materials pairing aimed on the jewelry market.

The MJP 300W 3D printer and VisiJet Wax Jewel Ruby materials are the newest additions to the additive manufacturing (AM) pioneer’s jewelry manufacturing line-up, and are mentioned to permit customers to ‘obtain new designs with larger design freedom and improved floor end.’

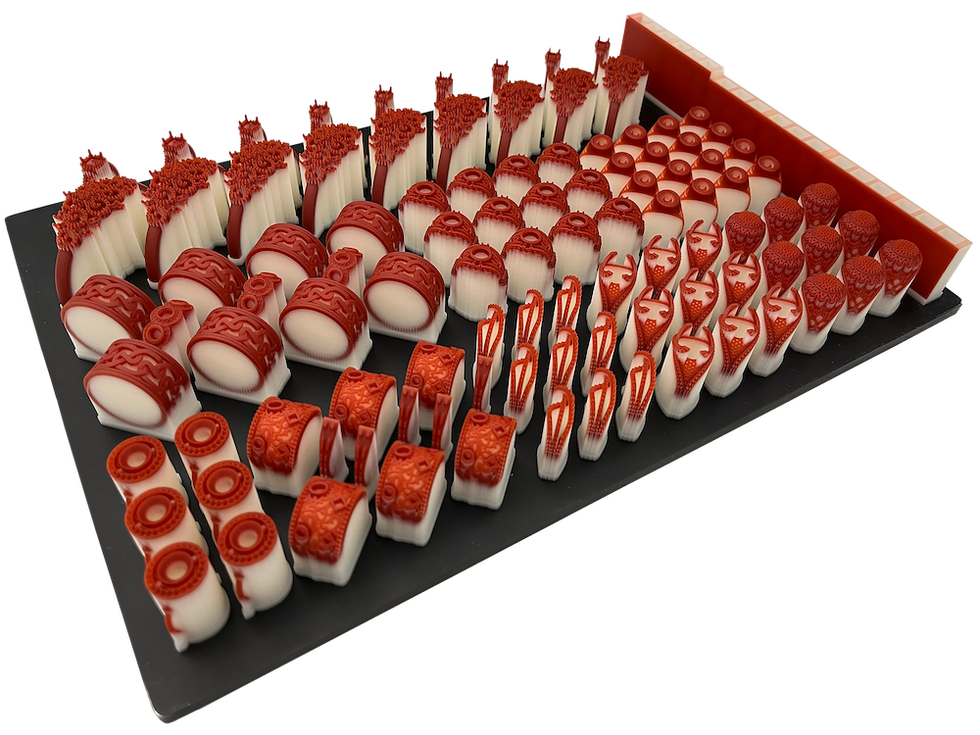

In response to 3D Programs, the MJP 300W is its most superior and versatile wax 3D printer to this point, and is being launched with the addition of two new print modes, QHD and UHD. QHD mode is claimed to allow greater than 50% improved decision in all axes (i.e., 2,000 dpi in X, 1,800 dpi in Y, 2,900 dpi in Z) and 9.5 µm layer thickness in comparison with the earlier era wax 3D printer, that means higher floor end and fewer post-processing. This makes it potential to print extra complicated designs the place sprucing shouldn’t be sensible or potential. Alternatively, UHD mode presents 2x quicker print velocity than XHD on its ProJet MJP 2500W Plus, elevated throughput and lowered labour for ending and sprucing. 3D Programs says the supply of 4 print modes (i.e., QHD, UHD, XHD, ZHD) presents improved flexibility in construct planning for each day and evening shifts.

On the supplies facet, VisiJet Wax Jewel Ruby materials is a troublesome, temperature-stable pure wax that gives the optimum mixture of versatile materials properties and good dimensional stability in high-temperature environments. In consequence, it’s potential to take care of particulars of essentially the most intricate jewelry designs throughout the moulding course of, lowering the probability of breakage or distortion. The corporate says patterns produced with this new materials have elevated thermal stability in comparison with the just lately launched VisiJet Wax Jewel Crimson. It additionally permits pre-setting of stones to speed up manufacturing of ultimate items.

Marty Johnson, vp, product & technical fellow, 3D Programs, commented: “With the introduction of the MJP 300W and our new VisiJet Wax Jewel Ruby materials, we’re offering producers of wax jewelry casting patterns with enhanced capabilities to enhance productiveness and processes that guarantee reliability. 3D Programs’ full system integration of the supplies, printer, print course of, and software program which is strengthened by our software experience and international buyer success crew is enabling our jewelry manufacturing clients to attain new ranges of innovation, high quality, and reliability. The most recent additions to our end-to-end options for jewelry manufacturing reinforce our dedication to addressing our clients’ wants to realize unprecedented ranges of agility with ease of use that ensures high-quality outcomes at any scale.”

The corporate says it has additionally made it simpler to watch print progress by way of the addition of an industrial stack gentle, which might be positioned on the printer or an adjoining floor to boost visibility. 3D Programs additionally claims that reliability enhancements by way of print head and {hardware} modifications will enhance the uptime and decrease the price of possession, by lowering alternative frequency.

Shashidhar Kumar at Shree Fast Applied sciences, a 3D Programs companion which had early entry to the machine and materials mentioned: “Our expertise has proven that’s it very straightforward to deal with, and delivers patterns with improved energy and adaptability, enabling us to offer larger high quality, sturdy patterns to our clients. Moreover, the fabric is greatest fitted to pre-setting stones, which helps our clients enhance efficiencies when creating items with intricate particulars.”

The MJP 300W and VisiJet Wax Jewel Ruby are each deliberate to be accessible in November 2023.

Earlier this 12 months, 3D Programs expanded its jewelry providing with the launch of the ProJet MJP 2500W Plus wax system, and later by way of the introduction of Determine 4 JCAST-GRN 20 resin for its Determine 4 stereolithography platform. Final month, the corporate introduced plans to deliver manufacturing of its metallic and polymer AM techniques in-house which is claimed to be enabling extra streamlined manufacturing and a discount in lead instances.