Time is working out! Nominate now for the 3D Printing Trade Awards 2023.

Australian large-format 3D printer producer AML3D has introduced a brand new prototype Nickel-Aluminium-Bronze (NAB) part order to assist the US Navy’s submarine program.

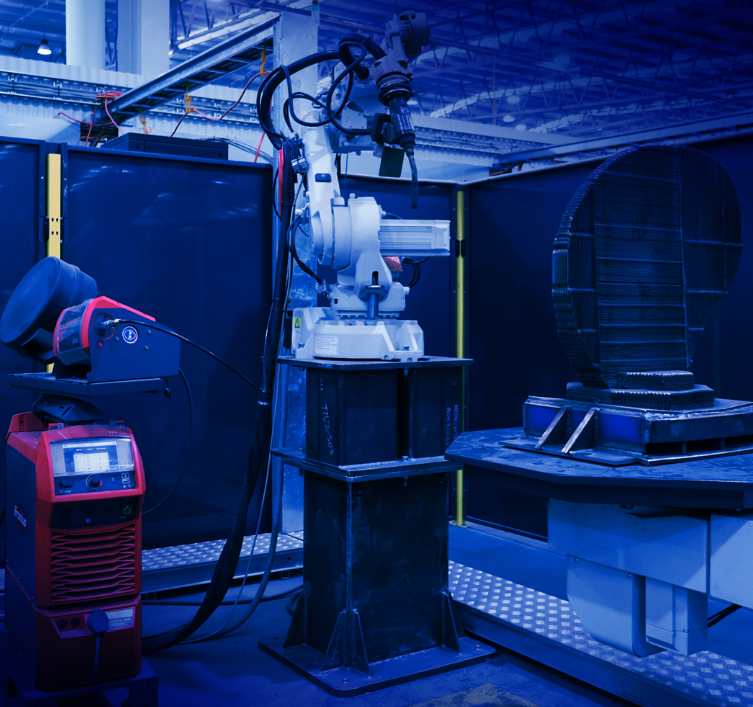

Value roughly $0.6 million USD, this order is for the manufacturing of a prototype half weighing round 1 tonne. This half shall be 3D printed utilizing AML3D’s proprietary ARCEMY Wire Arc Additive Manufacturing (WAAM) metallic 3D printer.

The order was acquired by BlueForge Alliance, a nonprofit, impartial integrator. The agency is working to assist the strengthening and sustainment of the US Navy’s submarine industrial base, by way of expertise acceleration and adoption.

The manufacturing cycle of the brand new prototype part is about to run for a interval of 22-24 weeks at AML3D’s Adelaide-based facility.

“It’s thrilling to see this growth of prototype part manufacturing utilizing AML3D’s proprietary ARCEMY expertise to assist the US Navy’s submarine industrial base. This order is one other alternative to show AML3D’s price efficient, excessive effectivity, prime quality, additive manufacturing expertise,” commented AML3D Interim CEO Sean Ebert.

“It is usually an important alternative to show the important thing function massive scale ARCEMY programs can play throughout the US Defence sector as level of want manufacturing options with the potential to unravel provide chain challenges for the US Navy.”

AML3D’s ongoing collaboration with the US Navy

In accordance with AML3D, this new order aligns with the corporate’s ongoing technique to scale up its operations within the US protection sector. The corporate hopes to change into some extent of want, additive manufacturing expertise answer to deal with provide chain constraints throughout the US Navy’s submarine program. AML3D highlights the US as being the corporate’s main progress market.

“AML3D’s US scale up technique is concentrated on growing and deepening our long-term, strategic partnership with key stakeholders throughout the US Navy’s submarine program. Our potential to ship contract manufacturing options that assist ARCEMY programs gross sales into the US Defence sector is a crucial a part of this technique,” defined Ebert.

The conclusion of the NAB prototype part order follows a lately introduced $1.51 million USD contract with the US Navy. This can see AML3D develop and 3D print high-demand, advanced, non-safety-critical, alternative NAB parts utilized in US Navy submarines. These parts are not obtainable by way of conventional producers.

AML3D is leveraging its ARCEMY 3D printers to supply the elements, that are mentioned to exceed the fabric power properties of equal forged elements. Beginning final month, this contract will run till June 2024.

AML3D has additionally lately introduced a contract extension to proceed NAB alloy characterization and power testing to assist the US Navy’s submarine program. This extension builds on the constructive outcomes of the corporate’s preliminary NAB alloy testing contract signed again in March 2023. Value round $280,000 USD, this contract extension sees testing happen at AML3D’s facility in Adelaide over a interval of 8-10 weeks.

AML3D can also be seeking to lengthen its Protection collaborations past the US. In accordance with Ebert, “This new NAB prototype part order can also be well timed within the context of the AUKUS Alliance partnership between Australia, the USA and the UK, and the alternatives AML3D might should entry extra Protection markets over the medium to long run.”

Steel 3D printing within the US protection trade

Steel 3D printing is actually a rising space within the protection trade. Earlier this 12 months it was introduced that metallic 3D printing firm Meltio had been acknowledged as a “strategic expertise companion” by the U.S. Division of Protection (DoD) for its metallic 3D printers. The corporate claims that this recognition strengthens its relationship with the US Military, opening alternatives with different US protection departments and armies around the globe.

Elsewhere, a Xerox metallic 3D printer was put in on the USS Essex final 12 months. Since this set up, the Wasp-class amphibious assault ship has served as a check mattress to guage the efficiency of the 3D printer on the open sea.

This challenge has seen sailors educated on tips on how to use the 3D printer, in addition to a sea testing program. This program includes a USS Essex-based group 3D printing a wide range of aluminum elements, and reporting outcomes again to NPS and Commander, Naval Air Drive, U.S. Pacific Fleet (COMNAVSURFPAC).

“Having this printer aboard will primarily speed up, improve and enhance our warfighting readiness. The capabilities of the 3D printer will allow Essex to change into extra self-sufficient,” commented Lt. Cmdr. Nicolas Batista, the Plane Intermediate Upkeep Division (AIMD) officer of the Essex.

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture exhibits a typical ARCEMY metallic 3D printing system. Picture by way of AML3D.