India is house to almost one and a half billion individuals, an unlimited potential marketplace for 3D printed healthcare purposes.

3D Printing Trade visited the Additive Manufacturing Society of India’s (AMSI) convention in Bangalore to study extra about using additive manufacturing on the earth’s second most populated nation. At AM 2023, we heard from medical specialists how they hope expertise may change the lives of thousands and thousands.

“Incorporating 3D printing applied sciences within the healthcare sector is a game-changer. It has the potential to remodel many lives by offering inexpensive, custom-made medical units and options to thousands and thousands of sufferers,” stated Dr. Anil Kumar P R, Scientist, Biomedical Wing, Sree Chitra Tirunal Institute for Medical Sciences and Know-how (SCTIMST).

Dr. Kumar defined that in India, the healthcare sector adopting 3D printing at a fast tempo. Principally, it’s used for orthopedic and dental purposes with steel 3D printed components. Polymer 3D printing can also be on the rise.

This text will present insights into the panel dialogue addressing the newest developments of 3D printed biomedical purposes: supplies, applied sciences, adoption, requirements and laws.

Learn extra insights from the twelfth Worldwide Convention on 3D Printing in Bangalore right here.

Supplies because the constructing blocks in medical 3D printing

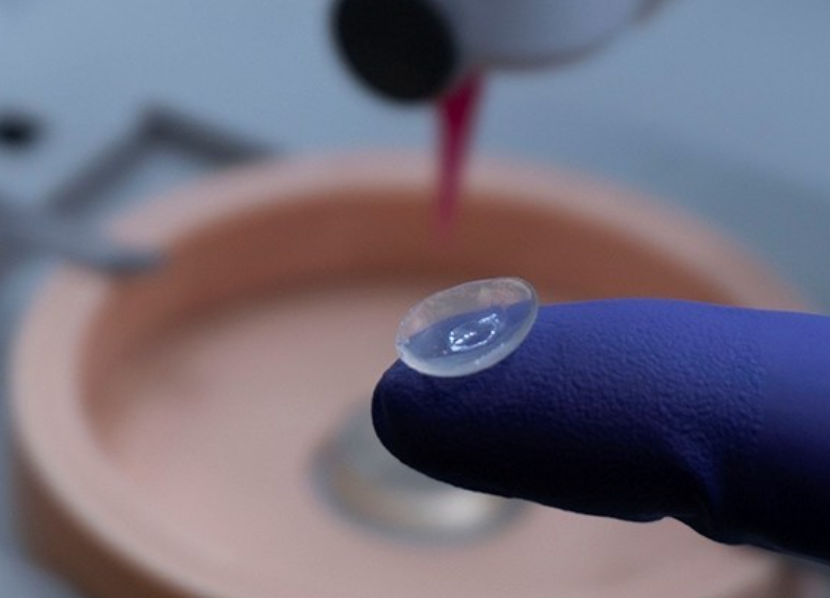

Dr. Shiny Velayudhan, Scientist ‘E’, Biomedical Know-how Wing, SCTIMST says the main focus of medical 3D printing will be broadly divided into two classes: 3D printing of implants and bioprinting, which entails 3D printing with dwelling cells. For load-bearing purposes, clinicians go for steel, at the moment titanium. Clinicians additionally work with ceramics, that are biocompatible supplies that are perfect for 3D printing implants and different medical units that have to be built-in into the physique. Some frequent ceramic supplies utilized in medical 3D printing embrace TCP, bio black, or hydroxyapatite.

In line with Dr. Velayudhan, these ceramic supplies usually are not very robust, which is unsuitable for top load-bearing purposes. In consequence, these supplies are employed for maxillofacial purposes. “Clinicians are searching for supplies which can be shapeable, which might be simpler to work with the scalpel. Consequently, they like supplies which can be composite, both ceramic or polymer,” explains Dr. Velayudhan.

Bioprinting is an rising class inside medical 3D printing. The “greatest materials,” based on Dr. Velayudhan, is collagen, noting it’s insoluble in water and will be troublesome to work with. Utilizing an acidic medium can overcome some challenges right here, she provides. “Relating to bioprinting, we print with cells, and cells die when the pH is above or under 7.3 to 7.8. Thus, collagen can’t be immediately used as a printing medium. Now we have to work with denatured collagen, which will be difficult. So, clinicians modify the gelatin and use it as a medium for bioprinting,” stated Dr. Velayudhan.

Medical 3D printing: applied sciences and adoption

As within the aerospace sector, 3D printing has “proved its mettle” for orthopedics and dental purposes, says Dr. Suman Singh, Principal Scientist & Head, MSSA, Central Scientific Devices Group (CSIR-CSIO), Advisor at Indian Girls in 3D Printing (IW3DP). She says, “Clinicians are keen to make use of custom-made implants created utilizing 3D printing supplies and applied sciences. However on the flip aspect, some clinicians are reluctant as a result of they don’t wish to go into the nitty gritty of any testing validations, laws, and so forth. So, except we put together ourselves for such phases, it’s going to be very troublesome for the adoption and commercialization of those applied sciences.”

Dr. Singh believes bioprinting is a blooming space, however at current, it’s “very nascent.” In line with her, “the broader 3D printing trade shouldn’t be that a lot explored within the Indian market. Motive being, there are not any motion plans, authorities insurance policies, laws, and so forth.,” she argued. In consequence, the adoption of 3D printing, whether or not it’s in biomedical or another vertical gained’t be doable with out correct consciousness and motion plans.

“We have to go deeper into the engineering aspect to truly make tissue engineering doable, which is the science behind engineering a cell to develop into a tissue after which doubtlessly a number of tissue sorts. Adoption and consciousness of 3D printing applied sciences within the medical sector has the potential to finish organ transplants that exist on the earth,” stated Alok Medikepura Anil, Co-Founder and Director at Subsequent Large Innovation Labs (NBIL).

Relating to supplies, 3D printers and their capabilities, panelists spoke about PEEK, which is a cloth that has biocompatibility and is already authorized. “This materials can be utilized for sure implants and rotating buildings that might be 3D printing utilizing common 3D printers proper from FDM applied sciences, SLA, SLS, and so forth,” stated NBIL’s Medikepura. “What we an organization, deploy for bioprinting is a pneumatic-based extrusion system, the place the uncooked materials might be within the type of pellets, or it might be within the type of semi-liquid materials that’s pneumatically managed by a system to providing precision.”

Want for requirements and laws

Dr. Velayudhan argued, “When experimenting, us clinicians check with ISO and [Organisation for Economic Co-operation and Development] OECD requirements, however for 3D printing particularly for bioprinting, we should not have any set requirements. Now we have to check with analysis papers as a substitute, which many industries and regulatory our bodies don’t consider, they ask us which customary is it? Thus, we’re once more caught there. In consequence, we want insurance policies so these processes will be streamlined.”

As for bioprinting, clinicians are at the moment challenged by scale. “There needs to be a expertise that permits for scaling as much as the human anatomical measurement,” she stated. “To do that, the employed bioprinter have to be very quick, as most of them are very gradual, which is a problem as a result of dwelling cells can’t be printed for hours at a time. Requirements and laws are the muse for a secure and efficient bioprinting future. With out them, we’re constructing on sand. We want clear requirements and laws to information the event and use of bioprinted tissues and organs and to assist the event of latest bioprinting applied sciences.”

Medikepura stated, “India must take a management place on this rising expertise, the sphere of additive manufacturing. For this to occur, regulatory insurance policies must be in place prepared for mainstream shopper adoption occurs.”

NBIL’s Co-Founder noticed that the Central Medication Normal Management Group (CDSCO) and medical councils usually are not as effectively outfitted to deal with a biomaterial that may be authorized to be used inside a human. He famous many researchers who’ve developed progressive biomaterials are scuffling with CDSCO approval. One constructive signal is that the U.S. Meals and Drug Administration (FDA), printed the Modernization Act in December 2022, which is permitting pharmaceutical corporations to start out taking a look at computer-based fashions, corresponding to synthetic intelligence (AI) vs. fashions and even alternate options to animal testing, corresponding to human-like tissues that may be developed within the lab utilizing bioprinters.

“Pharma corporations have acquired a inexperienced gentle from the bigger regulatory physique to go forward and use such fashions for growth of the brand new vaccines, for instance, which permits for fast-tracking the drug growth course of. It saves each a number of taxpayer cash in addition to the time to marketplace for crucial medication available in the market,” concluded Medikepura.

Who will win the 2023 3D Printing Trade Awards? Make your nominations now!

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

Featured picture reveals From left to proper: Alok Medikapura Anil, Dr. Suman Singh, Dr. Shiny Velayudhan being felicitated by Dr. Anil Kumar P R. Photograph by 3D Printing Trade.