BIM skilled Tekla has described how its software program and 3D modelling atmosphere have helped coordinate the assorted actions concerned within the building of Tideway’s Carnwath Highway shaft.

Tideway is a multi-billion-pound mission, designed to remodel London’s present 150-year-old sewer system with the development of a brand new 25km ‘tremendous sewer’ beneath the capital metropolis and River Thames. It has a fancy collection of building works, websites and shafts everywhere in the metropolis.

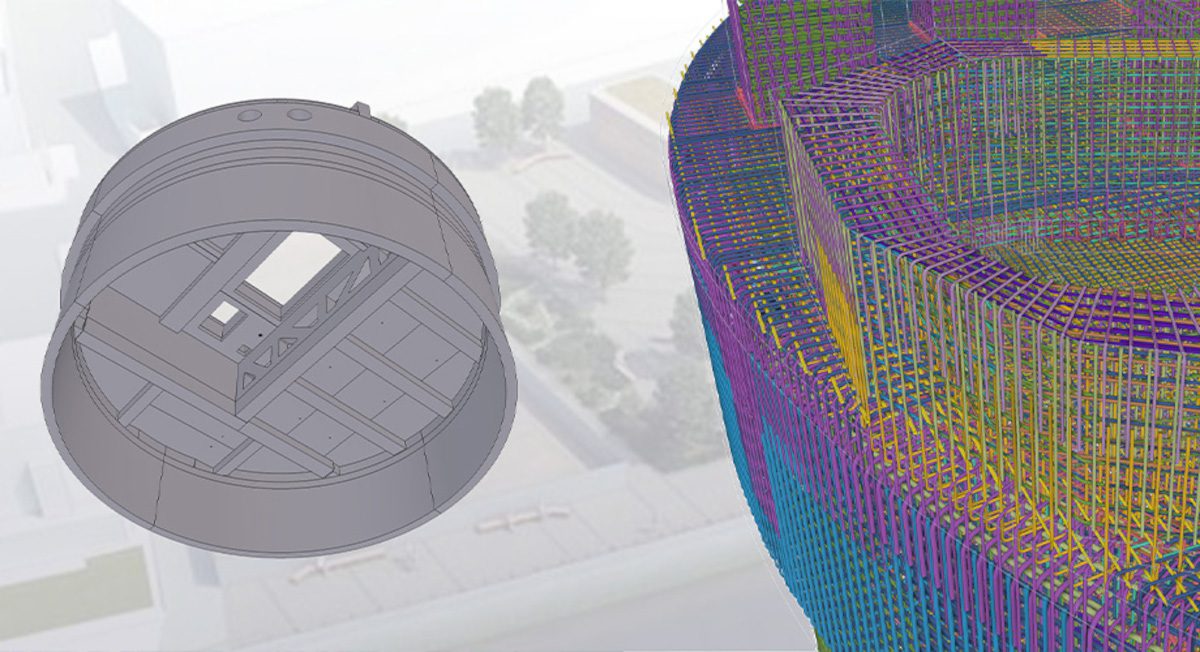

The Carnwath Highway shaft in Fulham is one instance, measuring 25 metres in diameter and with a depth of 42 metres. Initially constructed to launch the primary tunnel boring equipment for Tideway West, the shaft was subsequently used to extract the spoil from the tunnelling works, which, utilising the riverside location, may then be eliminated by barge. As soon as accomplished, the shaft will present a junction between three tunnels and have a mezzanine chamber degree for plant tools and entry. On the floor, the world might be landscaped to offer a public area on the north financial institution of the Thames.

Hewson Consulting, the civil, structural and geotechnical marketing consultant, was appointed by BMB Joint Enterprise in early 2022, tasked with detailing and modelling the higher shaft construction. Talking concerning the mission, David Wilson, Principal Engineer at Hewson Consulting, stated: “Whereas works had already commenced on the Carnwath Highway website once we had been appointed, BMB JV wished to discover modifications to the development methodology for the higher shaft construction, which fashioned the preliminary a part of our contract. The main target was on enhancing the effectivity and supply of the general programme schedule, which was understandably a key precedence.

“After consideration, a hung truss resolution was developed for the higher construction, enabling website groups to forged the slip-form secondary lining of the entire shaft in a single streamlined course of, somewhat than casting the shaft lining in two phases – the second of which might have required a colossal quantity of falsework supported off the bottom of the shaft.”

Along with the 2 underslung metal switch trusses, Hewson Consulting’s proposed design additionally featured 37 precast components.

“Coming into the mission at a barely later stage clearly got here with its challenges,” David continued. “Plenty of the advanced geometry had already been confirmed, following rounds of designs that got here beforehand. All different areas and the M&E fashions had been within the technique of being finalised as we had been engaged on the mission, that means that there was restricted scope to amend the present design geometry.

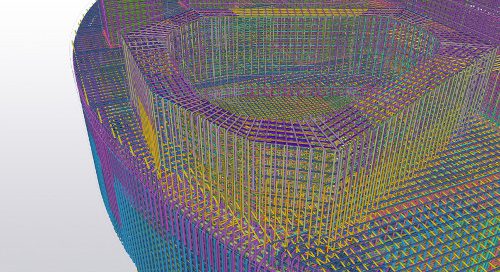

“We had been capable of mannequin all of those geometrically advanced interfaces and hold observe of design modifications in Tekla Constructions. By contemplating the design in an in depth 3D atmosphere, we may actually visualise how all the person components would work and match collectively on website. It could have been far more tough to ship the design to such excessive levels of accuracy with out Tekla software program and the 3D modelling atmosphere it supplies. This additionally helped us to determine any potential clashes, which we had been then capable of resolve earlier than reaching the location.”

Coordination and constructability had been understandably key components on the mission. In addition to coordinating with the assorted M&E components and the interfaces between the a number of precast and prefabricated members of the re-design, Hewson Consulting needed to additionally contemplate the shaft’s operation and upkeep necessities too.

David defined: “We had common conferences with Tideway and different stakeholders, throughout which we needed to show that we had been offering adequate area for the operations and website groups all through the redesign course of, and that there wasn’t going to be an impression on the pre-approved plans and techniques. With the ability to carry up the Tekla mannequin and visually show our plans and proposals was key in allaying these considerations.

“Equally, we had been ready to make use of the 3D mannequin to plan out entry and dealing strategies prematurely, which offered a serious security benefit. Working with precast concrete and taking a DfMA method, we needed to design the concrete components with sufficient tolerance to make sure the whole lot would match on website. By sharing the event mannequin with the location workforce through Trimble Join, we had been capable of get their suggestions on whether or not the design could be constructible or if there was enough area to soundly work. In essence, by with the ability to discover the mannequin because it was being created, the contractor workforce may benefit from a ‘digital rehearsal’ of the works.”

Working with strengthened concrete components offered one other problem on the mission, with the potential for some extremely congested areas of rebar and sophisticated detailing. By working in 3D, Hewson Consulting was capable of simply determine any congestion or potential ‘drawback areas’ and regulate the design in gentle of this.

David concluded: “The worth of the digital software program and the coordination and accuracy it supplied us was evident within the restricted variety of points we encountered because the works progressed on website. Likewise, the development of the slip-formed secondary wall lining ran extremely easily and was accomplished with zero points related to the reinforcement design detailed in Tekla.”

Tideway is predicted to be accomplished in 2025. Hewson Consulting’s work on the mission noticed the workforce win ‘Infrastructure Challenge’ within the 2023 UK Tekla Awards, with judges praising the wonderful mixture of metal and concrete buildings within the 3D mannequin and using Trimble Connect with collaborate with different workforce members as a ‘shining instance of innovation and excellence’.

On successful the award, David commented “I’m actually happy with the workforce who labored tirelessly to ship this mission, and this was solely made potential by means of Tekla Constructions which enabled quite a few customers to be working within the mannequin concurrently. To obtain the popularity from Tekla Constructions by successful the infrastructure class is the icing on the cake.”

For extra data, please go to: www.tekla.com/uk.