3D Printing Business attended the AMSI Worldwide Convention on 3D Printing in Bangalore.

Beforehand, we checked out additive manufacturing aerospace functions in India and developments within the Indian 3D printing market. On this article, we requested Wendt India, Indo MIM, EOS, Subsequent Huge Innovation Labs (NBIL) for his or her perspective.

These corporations unveiled their newest developments within the additive manufacturing (AM) business, showcasing AM supplies together with ceramics and biomaterials, 3D printed elements, 3D printers, and insights into their ongoing developments.

Learn extra from the twelfth Worldwide Convention on 3D Printing in Bangalore right here.

EOS showcases advanced 3D printed elements

3D printer producer EOS displayed advanced metallic and polymer 3D printed components on the exhibition. Gingadey L. Sudhakar, the Polymer Software Lead for India mentioned, the displayed components included dental implant, combustion chamber, automotive brake, and 3D printed seatbelt discovering their use within the dental, protection, automotive, and aerospace sectors. In keeping with the corporate, extra components are being produced in its facility. “The supplies employed within the creation of those elements included aluminium, chrome steel, titanium, and Inconel. A mix of metallic and polymer 3D printers was utilized within the manufacturing course of,” mentioned Sudhakar.

Subsequent Huge Innovation Labs talks about bioprinting

Subsequent Huge Improvements Labs’ (NBIL), Sriram Renganathan, Senior Gross sales Govt, shared insights into the corporate’s journey in bioprinting. He mentioned, “With a modest begin in 2016 and 20+ devoted workers, NBIL launched into a mission to advance bioprinting, dedicated to driving the way forward for regenerative medication and innovation via the transformative capabilities of bioprinting.”

Up to now, NBIL lent its 3D bioprinters, dubbed Trivima Professional (newest), Trivima Superior, and Trivima Primary to analysis establishments such because the Indian Institute of Know-how (IIT) Hyderabad and the Manipal Institute of Regenerative Medication for essential drug testing functions. Moreover, NBIL has plans to develop 3D bioprinted organs.

Wendt India reveals its partnership with Lithoz

Tamil-Nadu-based industrial manufacturing equipment firm Wendt India additionally exhibited its 3D printed components and know-how used. Mr. Arjun Raj P, the Firm Secretary, mentioned these elements discover functions in each dental and aerospace sectors and have been created utilizing in-house ceramics corresponding to silicon nitride, fumed silica, bioglass, piezoceramics, and extra. Notably, Wendt has partnered with Lithoz, using its ceramic 3D printer, dubbed CeraFab Lab L30 to create these components. Whereas the displayed 3D printed components served as demonstrations, similar elements are at present in manufacturing at its facility.

Shree Speedy Applied sciences shows metallic 3D printed components

Shree Speedy Applied sciences (SRT), a Mumbai-based 3D printing firm showcased its experience in metallic 3D printing, achieved by leveraging 3D Methods‘ DMP Manufacturing unit 350 metallic 3D printer. These components had been created utilizing supplies together with aluminum, maraging metal, chrome steel, copper, numerous grades of titanium, together with nickel, and cobalt chrome alloys from 3D Methods. Different displayed components included turbine blisk and rocket nozzle with functions within the aerospace and protection sector. In keeping with the corporate, extra elements are being manufactured.

Indo MIM reveals 3D printed components utilizing Laser Powder Mattress Fusion and Binder Jetting Applied sciences

Metallic injection molding (MIM) bureau, Indo MIM spoke about its know-how and 3D printed components created utilizing Laser Powder Mattress Fusion (LPBF) and Binder Jetting (BJT) applied sciences. Palwinder Singh, the Nation Supervisor of Gross sales & Advertising and marketing, mentioned, “Indo MIM’s intensive portfolio contains metallic injection molding together with ceramic injection molding, funding casting, and precision machining.”

The exhibited 3D printed elements, designed primarily for prototyping functions, had been developed utilizing supplies, together with maraging metal (18Ni300), Inconel 718, Inconel 625, SS 17-4PH, SS 316L, and Instrument Metal – H13. Singh mentioned that these elements are presently in energetic manufacturing.

Who will win the 2023 3D Printing Business Awards? Make your nominations now!

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

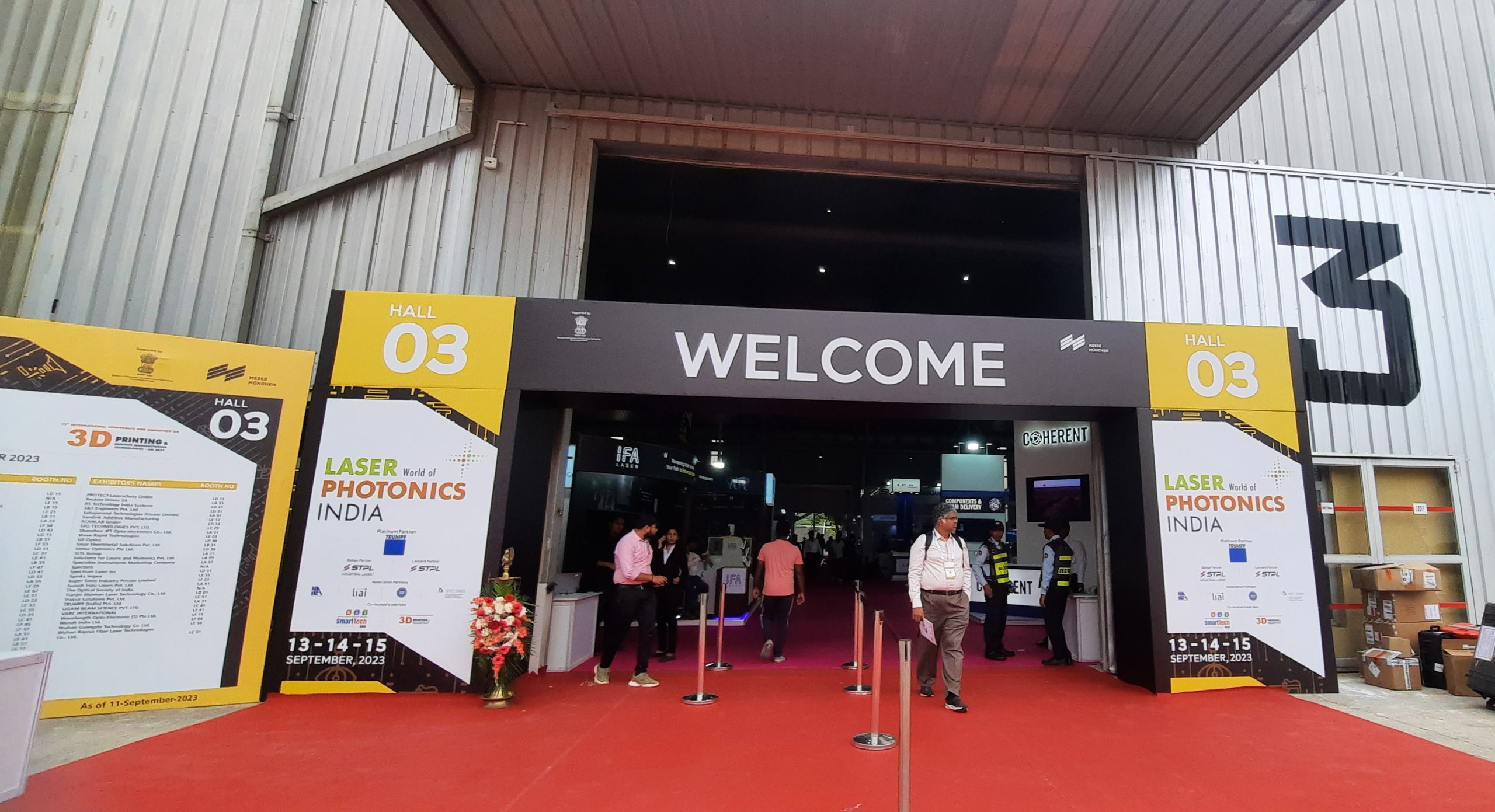

Featured picture exhibits the entry gate for the AMSI exhibition. Photograph by 3D Printing Business.