| Apr 08, 2024 |

|

|

|

(Nanowerk Information) Our muscle mass are nature’s excellent actuators — units that flip power into movement. For his or her dimension, muscle fibers are extra highly effective and exact than most artificial actuators. They will even heal from injury and develop stronger with train.

|

|

For these causes, engineers are exploring methods to energy robots with pure muscle mass. They’ve demonstrated a handful of “biohybrid” robots that use muscle-based actuators to energy synthetic skeletons that stroll, swim, pump, and grip. However for each bot, there’s a really completely different construct, and no normal blueprint for how you can get probably the most out of muscle mass for any given robotic design.

|

|

Now, MIT engineers have developed a spring-like system that may very well be used as a fundamental skeleton-like module for nearly any muscle-bound bot. The brand new spring, or “flexure,” is designed to get probably the most work out of any hooked up muscle tissues. Like a leg press that’s match with simply the correct quantity of weight, the system maximizes the quantity of motion {that a} muscle can naturally produce.

|

|

The researchers discovered that once they match a hoop of muscle tissue onto the system, very like a rubber band stretched round two posts, the muscle pulled on the spring, reliably and repeatedly, and stretched it 5 instances extra, in contrast with different earlier system designs.

|

|

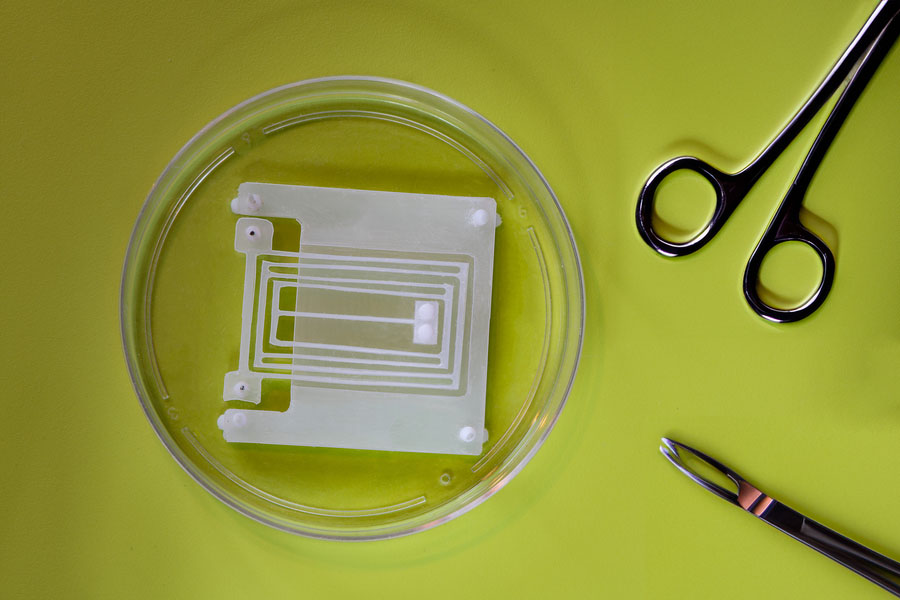

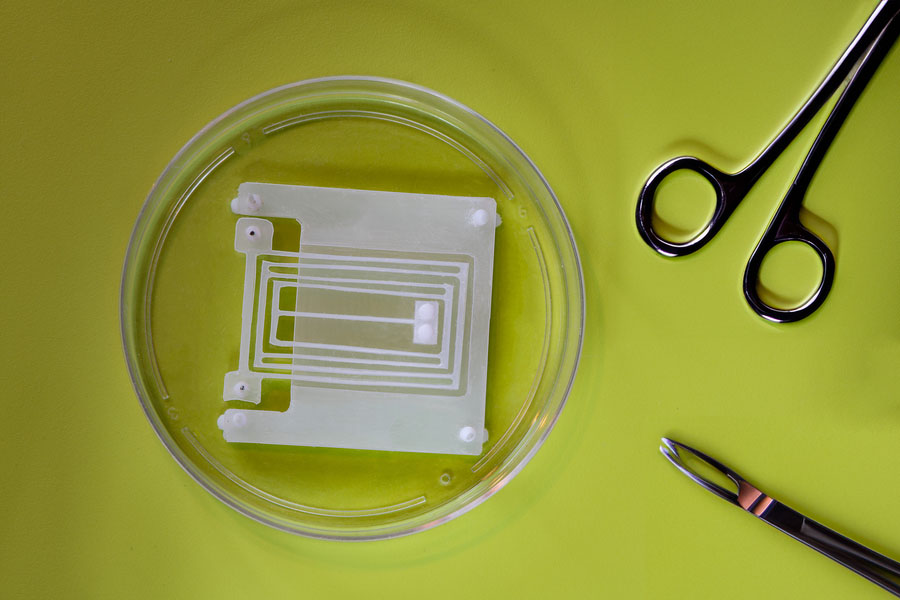

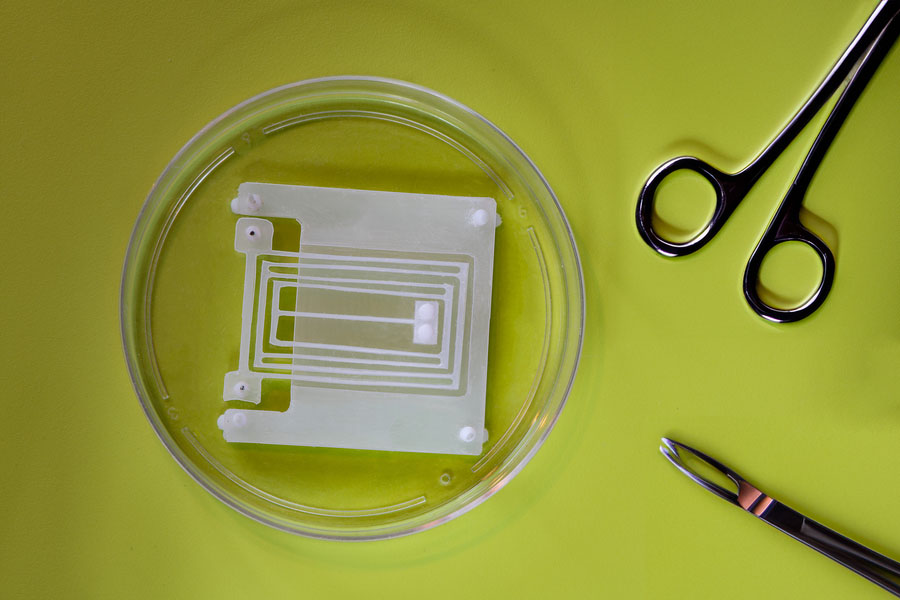

| MIT engineers have developed a brand new spring (proven in Petri dish) that maximizes the work of pure muscle mass. When residing muscle tissue is hooked up to posts on the corners of the system, the muscle’s contractions pull on the spring, forming an efficient, pure actuator. The spring can function a “skeleton” for future muscle-powered robots. (Picture: Felice Frankel)

|

|

The crew sees the flexure design as a brand new constructing block that may be mixed with different flexures to construct any configuration of synthetic skeletons. Engineers can then match the skeletons with muscle tissues to energy their actions.

|

|

“These flexures are like a skeleton that individuals can now use to show muscle actuation into a number of levels of freedom of movement in a really predictable method,” says Ritu Raman, the Brit and Alex d’Arbeloff Profession Improvement Professor in Engineering Design at MIT. “We’re giving roboticists a brand new algorithm to make highly effective and exact muscle-powered robots that do attention-grabbing issues.”

|

|

Raman and her colleagues report the main points of the brand new flexure design in a paper showing within the journal Superior Clever Methods (“Enhancing and Decoding the Efficiency of Muscle Actuators with Flexures”). The examine’s MIT co-authors embody Naomi Lynch ’12, SM ’23; undergraduate Tara Sheehan; graduate college students Nicolas Castro, Laura Rosado, and Brandon Rios; and professor of mechanical engineering Martin Culpepper.

|

Muscle pull

|

|

When left alone in a petri dish in favorable circumstances, muscle tissue will contract by itself however in instructions that aren’t solely predictable or of a lot use.

|

|

“If muscle isn’t hooked up to something, it would transfer rather a lot, however with enormous variability, the place it’s simply flailing round in liquid,” Raman says.

|

|

To get a muscle to work like a mechanical actuator, engineers sometimes connect a band of muscle tissue between two small, versatile posts. Because the muscle band naturally contracts, it could actually bend the posts and pull them collectively, producing some motion that may ideally energy a part of a robotic skeleton. However in these designs, muscle mass have produced restricted motion, primarily as a result of the tissues are so variable in how they contact the posts. Relying on the place the muscle mass are positioned on the posts, and the way a lot of the muscle floor is touching the submit, the muscle mass could reach pulling the posts collectively however at different instances could wobble round in uncontrollable methods.

|

|

Raman’s group seemed to design a skeleton that focuses and maximizes a muscle’s contractions no matter precisely the place and the way it’s positioned on a skeleton, to generate probably the most motion in a predictable, dependable method.

|

|

“The query is: How can we design a skeleton that almost all effectively makes use of the pressure the muscle is producing?” Raman says.

|

|

The researchers first thought of the a number of instructions {that a} muscle can naturally transfer. They reasoned that if a muscle is to tug two posts collectively alongside a particular path, the posts must be linked to a spring that solely permits them to maneuver in that path when pulled.

|

|

“We want a tool that could be very delicate and versatile in a single path, and really stiff in all different instructions, in order that when a muscle contracts, all that pressure will get effectively transformed into movement in a single path,” Raman says.

|

Delicate flex

|

|

Because it seems, Raman discovered many such units in Professor Martin Culpepper’s lab. Culpepper’s group at MIT specializes within the design and fabrication of machine components comparable to miniature actuators, bearings, and different mechanisms, that may be constructed into machines and programs to allow ultraprecise motion, measurement, and management, for all kinds of functions. Among the many group’s precision machined components are flexures — spring-like units, typically constituted of parallel beams, that may flex and stretch with nanometer precision.

|

|

“Relying on how skinny and much aside the beams are, you’ll be able to change how stiff the spring seems to be,” Raman says.

|

|

She and Culpepper teamed as much as design a flexure particularly tailor-made with a configuration and stiffness to allow muscle tissue to naturally contract and maximally stretch the spring. The crew designed the system’s configuration and dimensions based mostly on quite a few calculations they carried out to narrate a muscle’s pure forces with a flexure’s stiffness and diploma of motion.

|

|

The flexure they finally designed is 1/100 the stiffness of muscle tissue itself. The system resembles a miniature, accordion-like construction, the corners of that are pinned to an underlying base by a small submit, which sits close to a neighboring submit that’s match immediately onto the bottom. Raman then wrapped a band of muscle across the two nook posts (the crew molded the bands from reside muscle fibers that they grew from mouse cells), and measured how shut the posts have been pulled collectively because the muscle band contracted.

|

|

The crew discovered that the flexure’s configuration enabled the muscle band to contract principally alongside the path between the 2 posts. This centered contraction allowed the muscle to tug the posts a lot nearer collectively — 5 instances nearer — in contrast with earlier muscle actuator designs.

|

|

“The flexure is a skeleton that we designed to be very delicate and versatile in a single path, and really stiff in all different instructions,” Raman says. “When the muscle contracts, all of the pressure is transformed into motion in that path. It’s an enormous magnification.”

|

|

The crew discovered they may use the system to exactly measure muscle efficiency and endurance. After they different the frequency of muscle contractions (as an illustration, stimulating the bands to contract as soon as versus 4 instances per second), they noticed that the muscle mass “grew drained” at larger frequencies, and didn’t generate as a lot pull.

|

|

“Taking a look at how rapidly our muscle mass get drained, and the way we will train them to have high-endurance responses — that is what we will uncover with this platform,” Raman says.

|

|

The researchers are actually adapting and mixing flexures to construct exact, articulated, and dependable robots, powered by pure muscle mass.

|

|

“An instance of a robotic we try to construct sooner or later is a surgical robotic that may carry out minimally invasive procedures contained in the physique,” Raman says. “Technically, muscle mass can energy robots of any dimension, however we’re significantly excited in making small robots, as that is the place organic actuators excel when it comes to power, effectivity, and flexibility.”

|