A specialist crew from drainage and wastewater specialist Lanes Group plc has prevented the necessity to partially demolish three homes through the use of a water jet to take away concrete from a sewer pipe.

The ultra-high stress (UHP) jetting system, which powers the water jet to over the velocity of sound, was deployed after the muse concrete within the pipe proved too robust for typical robotic slicing.

The one sensible different would have been to excavate and change the pipe, buried three metres beneath extensions constructed behind the row of 9 terraces houses in Ilford, north east London.

That might have concerned the extensions for 3 of the houses being all however demolished, then reinstated, with the occupants positioned in momentary lodging whereas the work was executed.

Lanes carried out the UHP jetting challenge on behalf of Thames Water and has now used the method to finish different difficult concrete elimination tasks for the water firm.

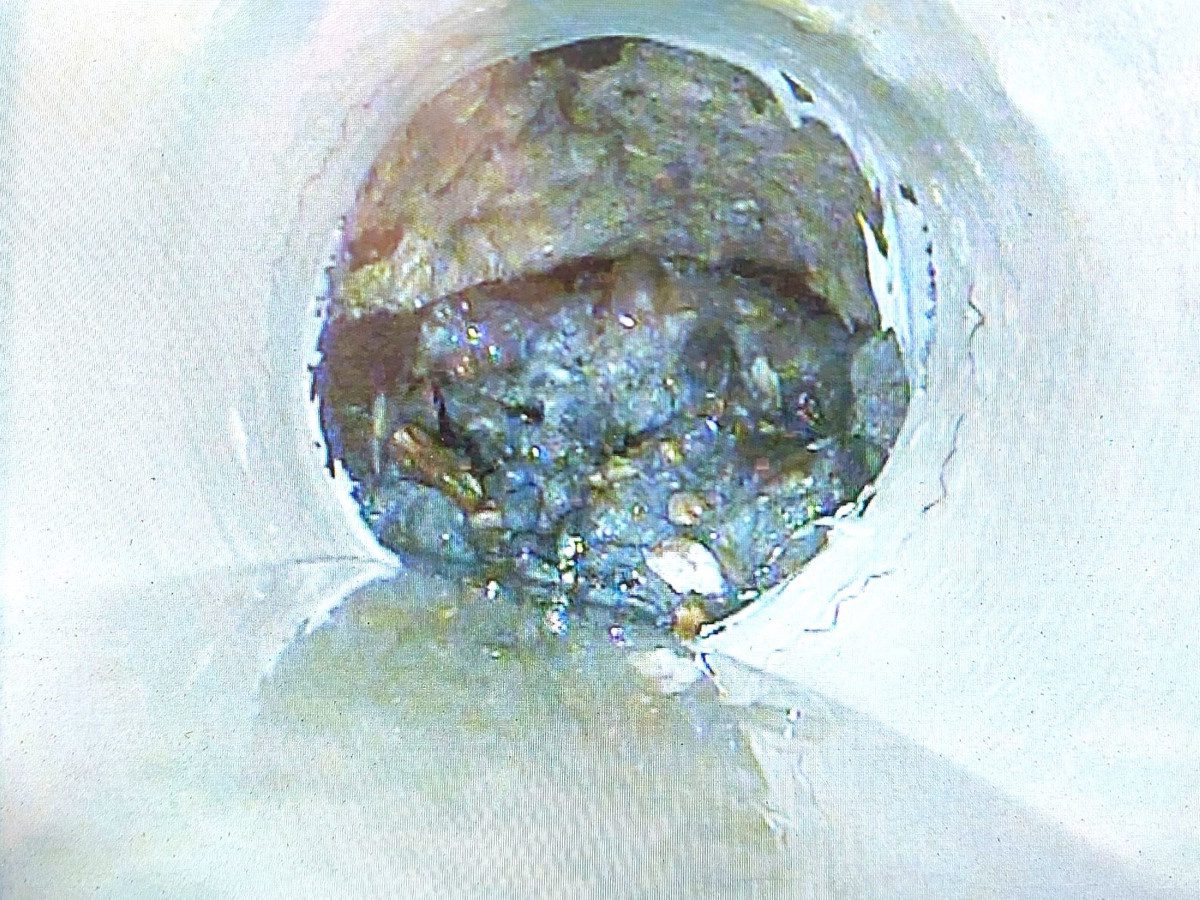

Lanes Operations Supervisor Calvin Could mentioned: “This was one of many hardest concrete elimination tasks we’ve ever tackled, and concerned contamination of a 150mm-diameter sewer.

“We imagine the concrete might have been linked to a close-by constructing challenge. Basis concrete is especially onerous and, on this case, had time to set strong, fully filling the pipe for 11 metres.

“We didn’t make very quick headway with a robotic cutter, which works by grinding down the concrete, so we would have liked a unique method.

“UHP jetting turned out to be a gamechanger. It was over 20 occasions as quick as utilizing robotic slicing and prevented the necessity for an alternate resolution that may’ve been far more expensive and disruptive.”

It meant the concrete could possibly be eliminated in 15 shifts, equal to a few weeks’ work.

Lanes, Thames Water’s wastewater community providers upkeep associate, developed a enterprise case for utilizing UHP jetting to make sure it will work and be cost-effective.

This led to the preliminary hiring of a UHP jetting system to make sure the concrete elimination course of was efficient – not least as a result of a tanker was having to go to the location daily to take away sewage build up behind the blockage.

Lanes chosen a Falch UHP pump mixed with an IMS Robotics jetting system, able to delivering a water jet at 2,500 bar (over 36,000 kilos per sq. inch).

Six Lanes wastewater operatives underwent Water Jetting Affiliation hydrodemolition coaching and gear provider instruction to provide them the information and expertise wanted to function the system.

The UHP jetting system has a jetting nozzle on the tip of a hose encased in a versatile metal coil sheath. As soon as guided into the pipe, a packer is inflated with compressed air to carry the nozzle firmly in place contained in the pipe.

A mini digicam and highly effective LED lights allowed the Lanes operative to then view the jetting operation, whereas controlling the nozzle with a joystick to direct it most successfully on the concrete.

The concrete was eliminated in one-metre sections, with the uncovered pipe strengthened by putting in a cured in place pipe (CIPP) level liner comprised of fiberglass matting, impregnated with resin.

As soon as the resin had cured, the liner created a sturdy new concrete-free pipe inside a pipe, with a design lifetime of a minimum of 50 years.

Lanes Group: www.lanesfordrains.co.uk