Time is working out! Nominate now for the 3D Printing Business Awards 2023.

Area system producer Redwire has efficiently 3D bioprinted a human knee meniscus on-orbit utilizing its upgraded 3D BioFabrication Facility (BFF) on the Worldwide Area Station (ISS).

The 3D bioprinted meniscus returned to earth onboard SpaceX’s Crew-6 Mission final month for additional evaluation, following profitable 3D print operations in July.

This achievement is claimed to unlock improved remedies for meniscal accidents in area, some of the widespread accidents for US Service Members.

“It is a groundbreaking milestone with vital implications for human well being,” commented Redwire Government Vice President John Vellinger. “Demonstrating the flexibility to efficiently print complicated tissue resembling this meniscus is a serious leap ahead towards the event of a repeatable microgravity manufacturing course of for dependable bioprinting at scale.”

3D printing a knee meniscus in area

As soon as 3D bioprinted, the meniscus was cultured on the ISS for 14 days in Redwire’s Superior Area Experiment Processor (ADSEP). The ADSEP is a totally automated, multi-use facility used to conduct a variety of life and physical-science analysis and small-batch manufacturing on board the ISS.

This 3D print was carried out as a part of the BFF-Meniscus-2 Investigation with the Uniformed Companies College of the Well being Sciences Heart for Biotechnology (4D Bio3). This Maryland-based biomedical analysis middle explores and adapts novel biotechnologies for navy functions.

NASA astronauts Frank Rubio, Warren Hoburg, and Stephen Bowen carried out this ISS-based investigation alongside UAE astronaut Sultan Al Neyadi.

Redwire’s on-orbit 3D printing capabilities

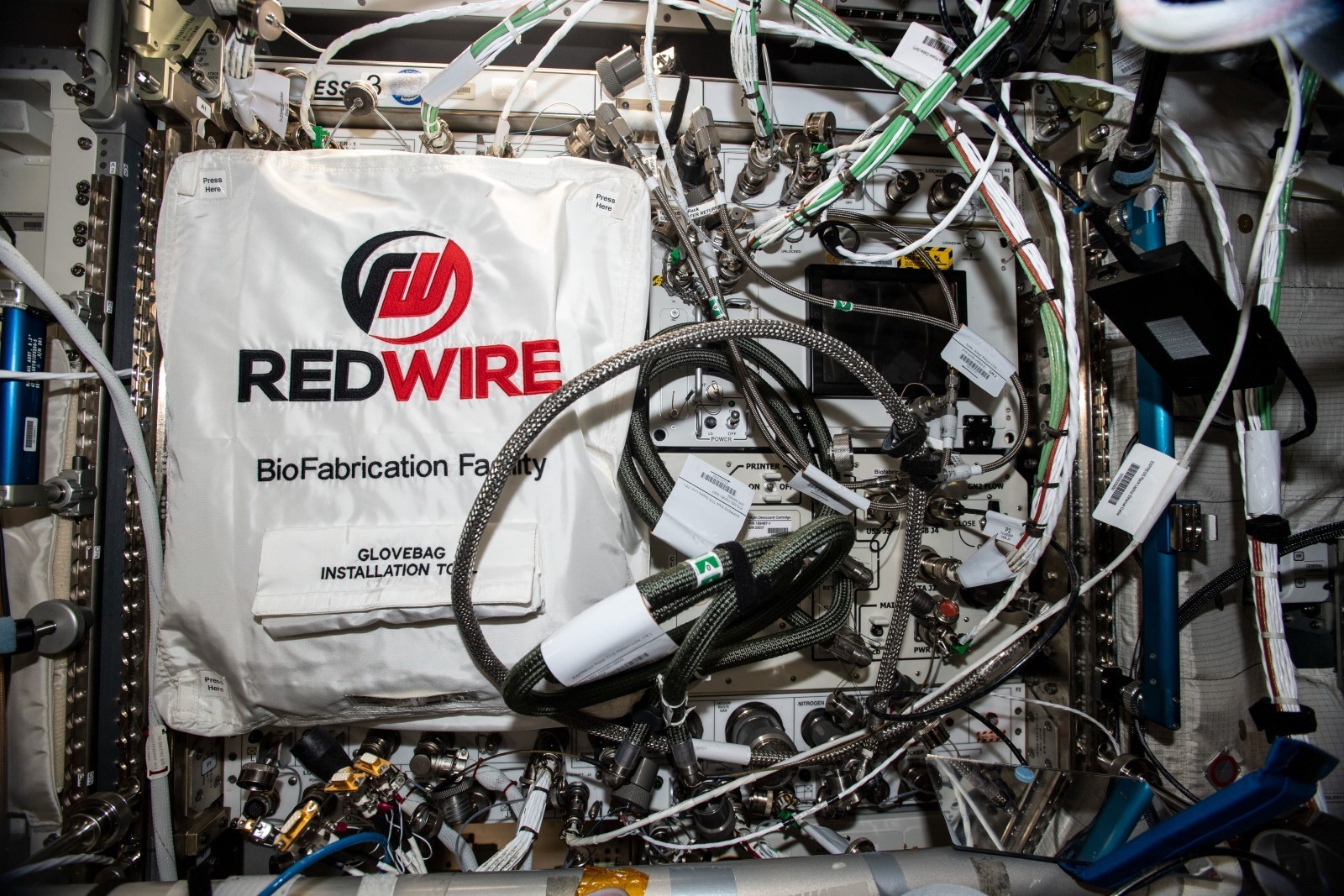

Redwire introduced plans to launch its upgraded BFF to the ISS final 12 months, with the 3D bioprinter being efficiently put in on-orbit in February 2023. The brand new BFF reportedly provides better temperature management when 3D printing with bioinks which can be temperature delicate.

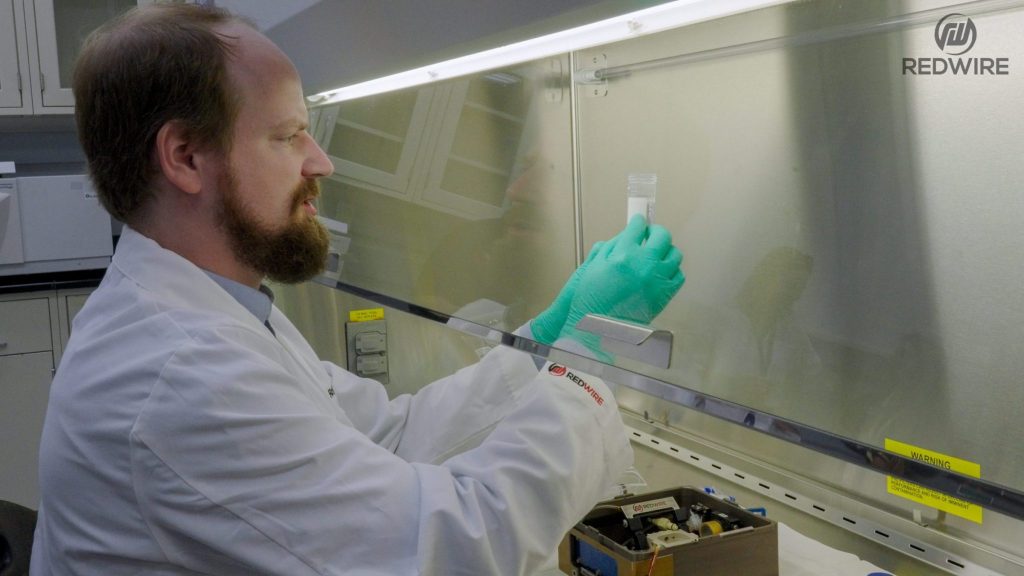

Redwire’s BFF and ADESP mix to make up the primary system able to 3D printing human tissue within the microgravity situations of area. The system exactly locations grownup pluripotent stem cells, 3D printing ultra-fine layers of bioink which can be a number of instances smaller than the width of a human hair. These layers can then be constructed as much as kind viable constructions.

To forestall the 3D bioprinted tissues from collapsing, the up to date BFF incorporates a Redwire-developed cell-culturing system that strengthens tissue over time. This course of can take between 12 to 45 days, and leads to the manufacturing of tissue that’s self-supporting below gravity. Seeking to the long run, Redwire hopes that this expertise might be honed to handle the scarcity of organ donors for transplant sufferers.

The upcoming SpaceX CRS-29 resupply mission to the ISS, going down on November 1, will see Redwire launch new microgravity analysis payloads into orbit. These payloads shall be focused in direction of pharmaceutical drug improvement and regenerative drugs, together with an experiment in bioprinting cardiac tissue.

ISS-based 3D printing

Over current years, the ISS has seen rising consideration inside additive manufacturing, with tutorial researchers and business enterprises looking for to check new 3D printing expertise below microgravity situations.

It was introduced earlier this 12 months that 5 Belgian firms and analysis facilities are collaborating to ship a 3D printed ‘heart-on-a-chip’ to the ISS as a part of the AstroCardia mission.

The 3D bioprinted synthetic coronary heart and circulatory system shall be despatched to orbit in 2025, and is being developed by Area Software Companies, SCK CEN, QbD Group, BIO INX and Antleron. The researchers hope that this mission will enable scientists to higher research the guts’s growing old course of, provided that the organ ages 20 instances sooner in zero-gravity situations.

French industrial 3D printer producer AddUp launched a steel 3D printer demonstrator to the ISS final 12 months. Developed as a part of the European Area Company’s (ESA) ‘Metal3D’ mission, AddUp constructed the interior construction and mechanisms of the 3D printer which was particularly designed to 3D print steel elements in area. The demonstarter processes wire feedstock affixed to its body, permitting it to function in microgravity situations.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture reveals Redwire’s BioFabrication Facility on board the ISS. Picture by way of Redwire.