Time is working out! Nominate now for the 3D Printing Business Awards 2023.

California-based 3D printing expertise firm T3DP has developed a brand new 3D printing materials combining a proprietary mix of recycled glass waste and Tethon 3D’s Genesis improvement resin. This innovation allows volumetric 3D printing for micro 3D photo voltaic and semiconductor functions.

3D Printing Business just lately requested T3DP Founder Daniel Clarke a couple of questions over e-mail to study extra about this new expertise, and its long-term advantages for additive manufacturing.

“With our course of we will print the massive molds from a UV curable polymer resin with ultra-smooth surfaces, forged the steel at room temperature, after which burn out the binder resin which is able to go away ultra-smooth metals and different supplies with an RA floor end of 1 µm and beneath in some instances,” defined Clarke.

T3DP’s new expertise was Impressed by the event of “Ultrafast Excessive-Temperature Sintering” (UHS) by researchers on the College of Maryland, which reportedly reduces sintering occasions to lower than 10 seconds.

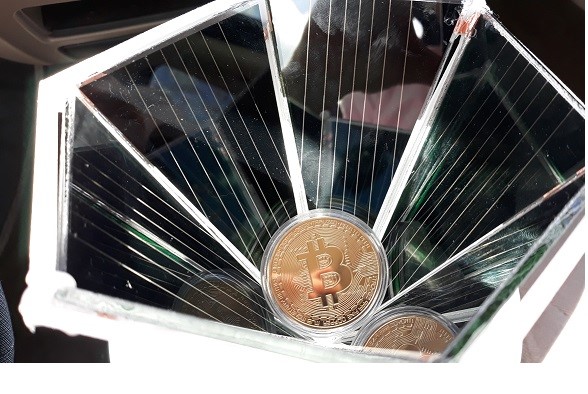

Sustainable semiconductor and photo voltaic cell manufacturing

Central to T3DP’s new expertise is the mixing of glass waste with Tethon 3D’s resin to create a novel materials with “distinctive properties.” Based on T3DP, this mix permits for next-generation volumetric 3D printing and molding of photopolymers. This permits the manufacturing of micro 3D photo voltaic cells/modules and superior semiconductor glass substrates, the place microchips and reminiscence could be positioned on the glass.

Conventional 3D printing strategies used for semiconductor functions usually depend on resource-intensive and wasteful processes. T3DP’s new methodology is alleged to sort out these challenges head-on, providing a sustainable different that enhances efficiency and reduces the carbon footprint of the manufacturing course of.

“This innovation has the facility to revolutionize not solely the 3D printing trade but additionally supplies analysis as an entire,” commented Clarke. “T3DP’s fusion of recycled glass and resin is a outstanding step in the direction of sustainable, high-performance manufacturing.”

Volumetric 3D printing and high-speed sintering

Throughout the manufacturing course of, T3DP leverages linear volumetric 3D printing to provide small sections of ultra-smooth molds, that are then stitched collectively to make a bigger mildew. Right here, the recycled glass waste is combined with Tethon’s Genesis improvement resin, with the glass then molded as a polymer.

Based on Clarke, the volumetric 3D printing course of can take seconds to minutes to finish, with the molding course of taking 10-20 seconds for big space substrates measuring 6” x 6”.

The volumetric 3D printed ‘inexperienced components’ are then sintered utilizing the UHS expertise from the College of Maryland. This novel sintering course of combines radiant and get in touch with warmth to realize fast and uniform heating of the fabric as much as 3000?. Sintering is reportedly accomplished in below 10 seconds, greater than 1000 occasions sooner than typical furnace sintering. This high-speed sintering expertise is being commercialized by College of Maryland spinoff HighT-Tech.

Optimizing semiconductor and photo voltaic cell manufacturing

When manufacturing semiconductors with this new expertise, T3DP makes use of fused silica to create 3D glass interposes. This bypasses the necessity for typical electronics 3D printing processes, together with direct writing, etching, and lithography.

“These are advanced microstructures,” defined Clarke. “We bypass Lithography, (Direct Writing for Interconnect Strains), and Reactive Ion Etching by simply molding the entire construction in a single piece for 3D Photo voltaic and Semiconductor Glass Substrates.”

Based on Clarke, this course of ends in a computing energy improve of greater than 8 occasions, with extra chips and reminiscence capable of be “crammed right into a smaller footprint”, leading to 50% power financial savings. Clarke added that T3DP has “a particular proprietary combine that makes the glass 10x stronger, making it proof against fracture.”

Moreover, T3DP’s new expertise is alleged to optimize the manufacturing of micro 3D cells/modules.

These elements are mentioned to supply year-round reliability, and embody 3D surfaces able to capturing extra daylight from 7 am to 7 pm. Furthermore, Clarke claims that T3DP 3D printed photo voltaic cells/modules supply 15-100% extra power in the identical floor space whereas boosting energy by 39% in scorching areas. Clarke additionally said that micro 3D photo voltaic cell substrates can’t be made by way of typical glass manufacturing strategies.

The way forward for T3DP’s expertise

Based on Clarke, this new expertise possesses vital potential for the 3D printing trade. “Our molding is materials agnostic. At present we will solely do ceramic and glass,” defined Clarke. “Bucktown Polymers is growing a brand new casting resin which is able to make our course of materials agonistic to work with virtually any materials, as its a chemical curing 3D printing resin as an alternative of photocuring.”

Clarke additionally highlighted some great benefits of T3DP’s new course of over that of electric-car producer Tesla, which is utilizing giant sand molds to giga forged their automobile chassis.

“With our course of we will print the massive molds from a UV curable polymer resin with ultra-smooth surfaces, forged the steel at room temperature, after which burn out the binder resin which is able to go away ultra-smooth metals and different supplies with an RA floor end of 1 µm and beneath in some instances.”

When it comes to the commercialization, Clarke claims that T3DP is at expertise readiness stage 7. In different phrases, prototypes of the corporate’s recycled glass waste and Tethon resin have been efficiently demonstrated in an operational surroundings.

Trying to the long run, Clarke is assured of a swift path to market, “[We] ought to have the molding commercialized in lower than 12 months.” Clarke additionally highlighted that volumetric 3D printer developer Xolo is commercializing T3DP’s volumetric 3D printing expertise in Europe, “however should license the IP (mental property) as soon as they promote within the USA.”

Moreover, Clarke said that the method for producing the 3D photo voltaic elements “needs to be commercialized in 18 months, possibly sooner.”

Glass 3D printing

Glass-based 3D printing is nothing new. Earlier this 12 months it was introduced that Austrian ceramic 3D printing firm Lithoz had partnered with glass producer Glassomer to launch LithaGlass, a high-performance fused silica glass.

This materials is optimized for Lithoz’s Lithography-based Ceramic Manufacturing (LCM) expertise. The corporate claims that the composite slurry, which has a quartz glass base, could have a major impression on the sphere of ceramics 3D printing.

Elsewhere, researchers on the US Division of Protection-backed MIT Lincoln Laboratory developed a low-temperature strategy to 3D printing glass objects final 12 months. Not like typical glass 3D printing and post-processing, which entails exposing components to temperatures of 1,000? or extra, this course of entails layering a customized, highly-filled ink, that’s curable at 250°C.

“We envision this versatile supplies platform, when mixed with multi-material additive manufacturing, will allow the fabrication of all kinds of strong microsystems,” the researchers defined of their paper.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of obtainable roles and kickstart your profession.