With the event of the knowledge period, sensors able to transmitting and detecting info have develop into the main strategy to acquire info. Subsequently, constructing a sensor system with a large detection vary, excessive sensitivity and quick response is crucial.

Lately, graphene supplies have obtained growing consideration for sensor functions because of their glorious electrical conductivity and bodily, optical, thermal, and structural properties. These functions primarily embrace the detection of bodily properties reminiscent of strain and mechanical pressure, chemical substances reminiscent of glucose, dopamine, proteins, heavy metals and natural pollution, in addition to the detection of gasoline, temperature and humidity.

In a brand new paper revealed in Mild: Superior Manufacturing, scientists led by Physician Zhengfen Wang and Professor Xi Chen from the College of Shanghai for Science and Expertise have reviewed laser-scribed graphene (LSG) for sensor fabrication.

Graphene has been ready with varied strategies, reminiscent of mechanical exfoliation, chemical vapor deposition (CVD), epitaxial progress, and chemical discount of graphene oxide. Excessive-quality graphene will be obtained by mechanical exfoliation, however the low effectivity prevents the large-scale manufacturing of graphene.

The CVD methodology is taken into account probably the most promising methodology for getting ready massive areas and high-quality graphene, however the CVD methodology is constrained by excessive power consumption and price. Graphene movies ready by the epitaxial progress methodology have good electrical conductivity and excessive optical transmittance. Nonetheless, they require high-temperature processing, power consumption and switch value. Chemical discount of graphene oxide is low in value and excessive in effectivity however creates environmental air pollution issues through the preparation course of. Subsequently, graphene’s low-cost, high-efficiency, pollution-free preparation strategies stay very fascinating.

The laser direct writing method has lately attracted analysis functions in varied fields because of its distinctive benefits of selective and localized discount, exact and quick patterning, and the absence of masks and extra chemical substances. With the laser direct writing method, a laser is used to irradiate the carbon precursors and generate graphene by in-situ scribing. The entire laser scribing course of takes only some minutes, which considerably improves the effectivity of getting ready graphene.

The wonderful properties of excessive floor space, excessive thermal stability, and excessive electrical conductivity exhibited by LSG movies have led to its use in all kinds of functions. These functions embrace photodetectors, sensing, power storage, memristors, holography, antibacterial functions and antennas.

The analysis group mentioned the preparation and modification of LSG, which will be ready by completely different laser mild sources and precursors, together with carbon precursors reminiscent of GO and PI. Standard graphene preparation strategies are energy-intensive, pricey, or environmentally unfriendly, however this laser scribing methodology for graphene preparation overcomes these drawbacks. The LSG will be modified in a single step by adjusting the laser parameters, ambiance, and doping. The excessive floor space, good electrical conductivity, and easy and environment friendly fabrication means of LSG make it glorious potential for sensor functions.

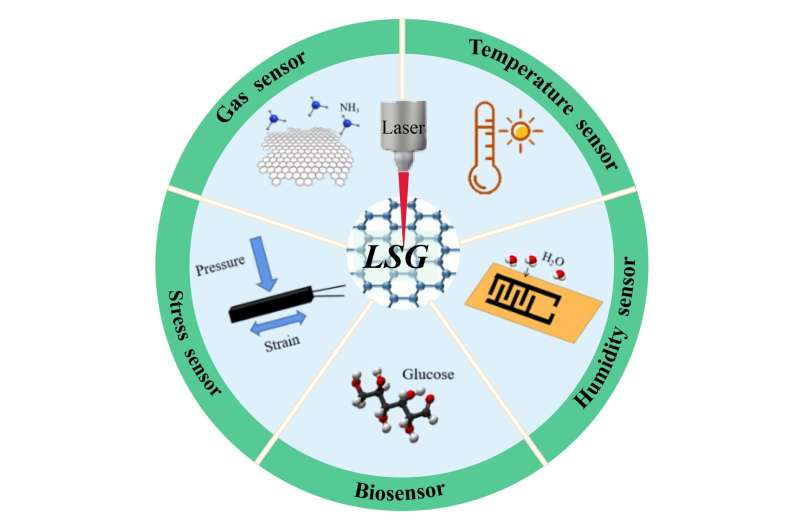

The analysis group summarized the functions of LSG in stress sensors, biosensors, gasoline sensors, temperature sensors, and humidity sensors. The efficiency of the sensors will be optimized through the use of the suitable laser energy, scan pace, scan spacing, and appropriate doping within the preparation of the LSG. For multifunctional sensors, the crosstalk between completely different indicators will be lowered by structural designs and patterning. Specifically, the versatile patterned preparation and varied versatile substrates make LSG additionally promising for wearable sensor functions.

Extra info:

Xing Liu et al, Laser-scribed graphene for sensors: preparation, modification, functions, and future prospects, Mild: Superior Manufacturing (2023). DOI: 10.37188/lam.2023.011

Quotation:

Laser-scribed graphene for sensors (2023, October 5)

retrieved 6 October 2023

from https://phys.org/information/2023-10-laser-scribed-graphene-sensors.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.